Bo Dennis teaches crop production in Kennebec Valley Community College’s Sustainable Agriculture program. He’s also the manager at the school’s 120-acre organic farm in Hinckley and, as such, spends plenty of time with his hands in the dirt. But these days he also spends a lot of time with a computer and a 3-D printer, producing inexpensive high-tech fixes to a few farm problems.

KVCC is making watering devices for chickens, houses for pollinators and the latest application, seed rollers, items that look like hockey pucks with holes in them. Their function? Making planting row crops easy and efficient.

“The printer is always going,” Dennis said.

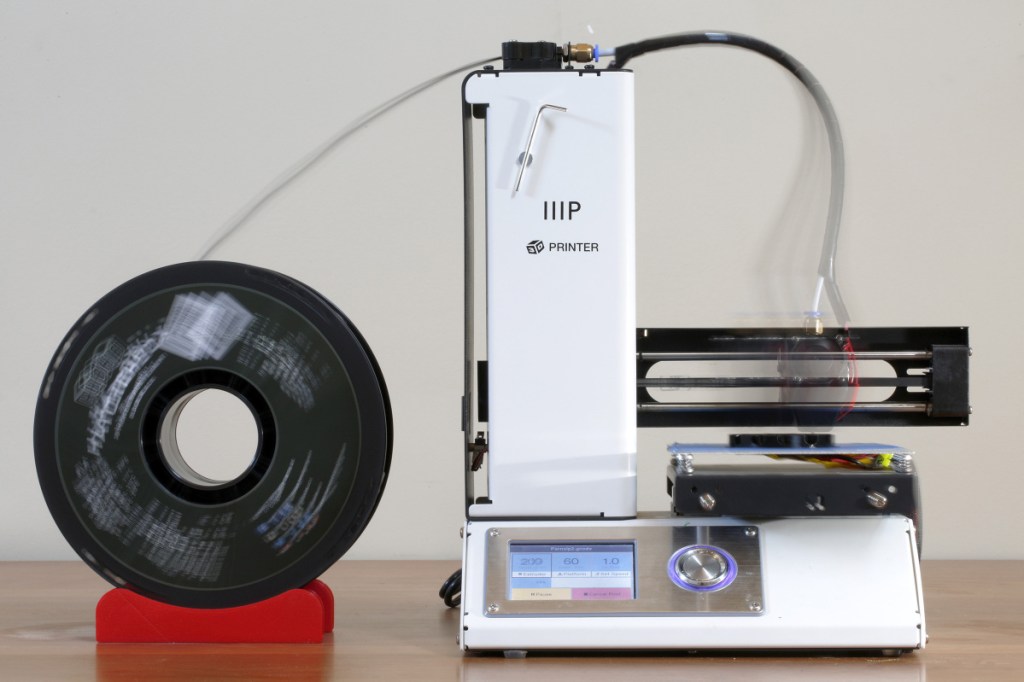

Actually, printers. Kennebec Valley Community College in Fairfield first purchased a 3-D printer for the school library at the request of Diane Sauter-Davis, the chair of the school’s Occupational Therapy Assistant program. When it arrived, according to Ben Crockett, KVCC sustainable agriculture department chair, no one really knew what to do with it. “Just like when the first fax machine came into the office,” he said.

But as the sustainable agriculture department embraced it for these farm applications, the school began ordering more and now has a dozen in the library, Crockett said. Each of the 3-D printers costs under $200.

“We are trying to keep this really affordable,” Crockett said. Since these 3-D printers aren’t exactly top of the line, they tend to be fussy, he said. “You have to do a lot of hands-on tinkering.” Which is how Crockett came to learn how to solder this year.

PENNIES ON THE DOLLAR

It all started during a one-week session on using the 3-D printer earlier this year. These kinds of printers melt various kinds of filaments, including plastic, and build objects one thin layer at a time, using blueprints written in code that users either create themselves, or get from sharing services.

The first farm use for the 3-D printer came from agriculture major Sarah Fallon, who figured out a way to make the nipples used for giving chickens water. (In addition to row crops, the school raises sheep, chickens, pigs and turkeys.) The chicken waterers cost pennies on the dollar compared to the ones the school had been buying. And the inexpensive filaments they use are made from corn syrup, and thus biodegradable.

Kennebec Valley Community College farm manager Bo Dennis, left, and department chair Ben Crockett demonstrate how a 3-D-printed seed wheel is slotted within a precision seed spreader.

“Over time it would basically turn back into corn syrup and dissolve into the earth,” Crockett said. “We don’t have to worry about putting any petroleum products into the farm.”

The school has owned the farm since 2013, when it purchased the former dairy operation with the help of private donations and a $2.5 million federal grant. The farm had belonged to the Good Will-Hinkley School, which used it for educational purposes as well. KVCC students and faculty grow about 3 acres of Maine Organic Farmers and Gardeners Association-certified organic vegetables, fruits, herbs and flowers.

Dennis found the plans for the seed roller on farmhack.com; downloading them was free.

The part fits Jang seeders, a classic farm tool that makes planting fast and efficient. The basic model (for sale at Johnny’s Selected Seeds for about $400) is roughly the size of a second-grader’s bike, and can either be hand-rolled across a field or attached to a tractor. The seeding machine digs a furrow of just the right depth, drops the seed at perfectly regular intervals and then covers it with soil, like magic.

But seeds vary in size, and so do the seed rollers that fit into the Jang seeders and do the work of distributing the seeds evenly. One size will work for onions, carrots, radishes and kale; another is good for basil, beets and chard, and every time you buy a new size, you’re likely to pay between $20 and $26. The company offers at least 20 different versions of the roller. To get your head around why so many are needed, consider that planting a delicate, almost fly-away carrot seed is very different from, say, planting a big, flat zucchini seed. So far, so good with the seed rollers.

“We used them today,” Dennis said. “We planted beets.”

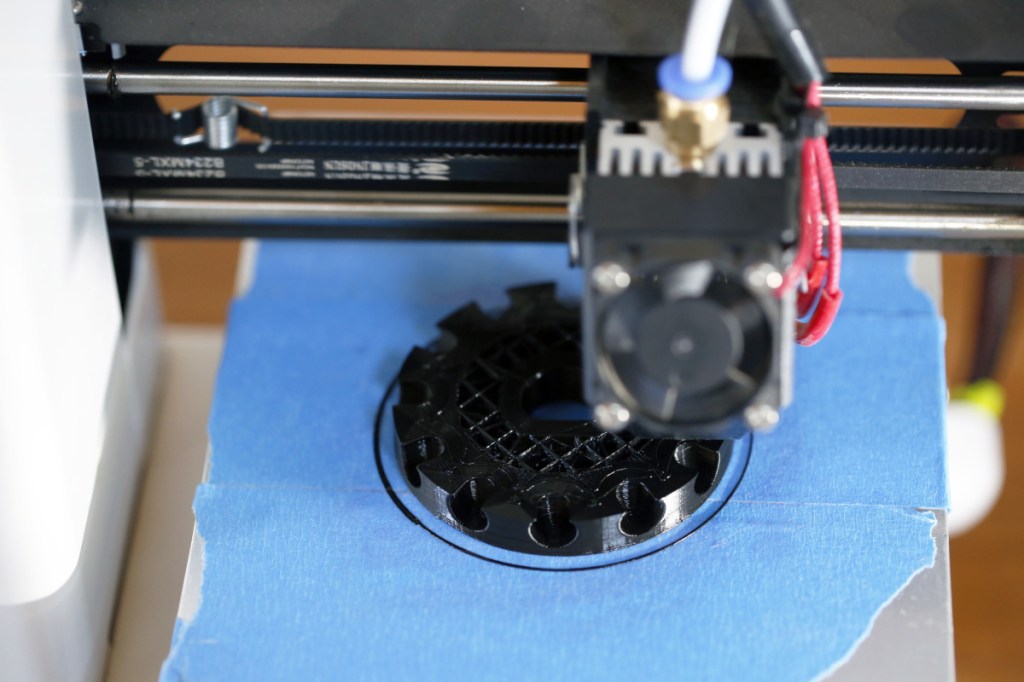

He wasn’t completely satisfied with it though, so he’ll likely tweak the next version – another joy of making something with a 3-D printer; you go back to the drawing board, as it were, make an adjustment in the code, then push print again. The setup takes just 10 minutes, though printing time ranges between 2 and 6 hours. The plastic ends up with a rougher texture than a purchased item. On the plus side, the objects are tailored to KVCC’s very specific needs. Next up, spinach seeding and making a roller that works on pelleted parsnip seeds (seeds coated in a thin coat of clay to make them easier to plant).

A 3-D printer churns out a seed wheel at KVCC.

How desirable is a cheap version of a Jang seed roller? Crockett estimates it costs the college about $1 to make them or about 4 percent of the retail cost. After Dennis posted a photo on Instagram with one of the 3-D printer-made seed rollers, he got requests from Two Farmers Farm in Scarborough, Crystal Spring in Brunswick and Riverweb Farm in Avon; all wanted to give it a trial. At Crystal Spring, farmer Seth Kroeck asked for a seed roller sized to fit a customized Jang he uses that lays two rows of seed at a time. “Bo, being able to do the CAD (computer-aided design) work, is making me something that is not available anywhere else,” Kroeck said. His plan was to give it a try on pelleted parsnip seeds.

Riverweb Farm’s Jos Thalheimer said he doesn’t lack for Jang seed rollers, but he contacted KVCC because he wants a better version of them. He bought about 10 of the most common when he founded Riverweb and started planting four seasons ago. He loves the machine, but finds the rollers are not always sized right. “I have probably bought what feels like another 20 since then,” Thalheimer said. “They are not cheap, and I would be more than willing to buy them, but they need to work. It is frustrating to own what feels like a complete set of rollers and still find pretty regular applications where they are not doing the job correctly.”

For instance, last year, Riverweb farmers had a terrible time trying to roll out pelleted beet seed. What Thalheimer is looking for is a true hack then, something that tinkers with the roller in a way that makes it just right for him. He hasn’t gotten any trial rollers from KVCC yet, but he’s hoping to in time for planting season.

BEE HOME

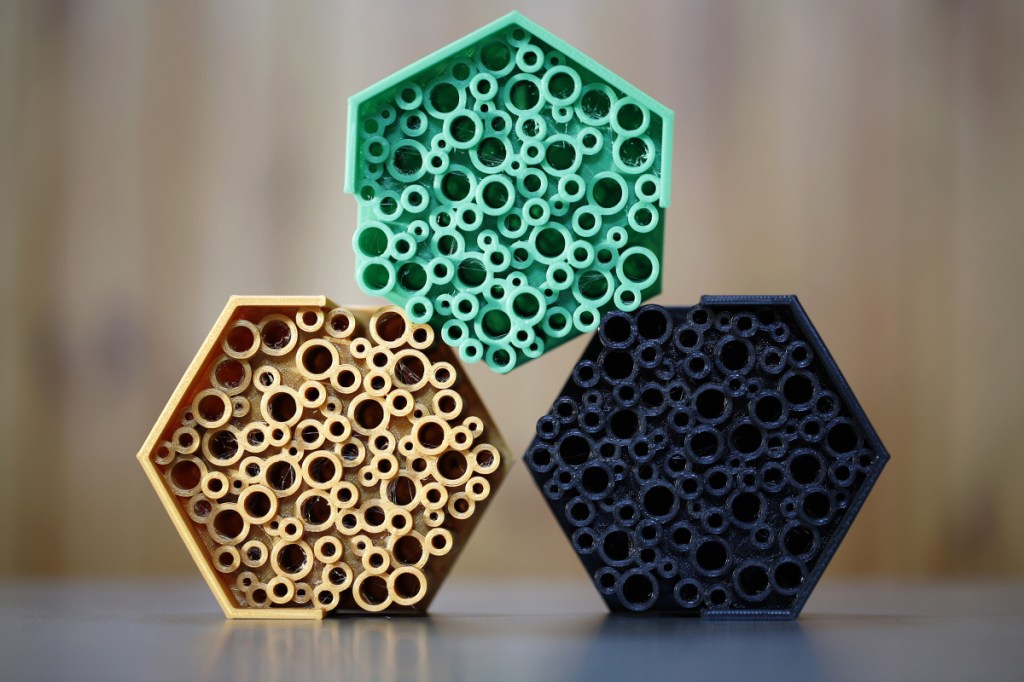

It’s been a learning curve for the faculty members, from soldering to looking for other uses for the printer. Crockett focused on making a series of tubes that they hope will serve as housing for pollinators in the college’s orchard. Bees, whether mason or bumblebees, tend to burrow into rotten wood to lay eggs and hibernate. If you take a piece of wood, drill holes in it and put it out for the bees, theoretically they’ll find it, mark it by filling the holes with mud, and then anyone who wants to keep them safe – from the harshest winter temperatures or from hungry predators, like bears – could pick up the wood and move it into a shed or some such.

Crockett’s goal is to increase the number of pollinators that stick around the area by building them a deluxe home, and thus increase the output from the orchards.

With the 3-D printed tubes, Crockett plans to experiment with colors. He’s printed them with black, green and gold filaments. Will the bees prefer the black, for the warmth it might retain from the sun? He has no idea, but if they don’t like it, it’s an easy item to toss in the compost heap.

Because the machines are so cheap, they do require maintenance, but for each item that breaks, Crockett says he has been able to find advice and tutorials online showing him how to fix problems. “There is this wire failure on part of the machine that happens all the time,” he said, “like the way with a Subaru, you know the heat shield is going to come off.” (True.)

He considers it healthy for students to learn how to make those fixes too. And to dive into other cool agricultural needs that can be met with a 3-D printer and some biodegradable filament. The barriers are minimal, he said.

“If you are willing to sit through a 20-minute tutorial, it isn’t much harder than video games,” Crockett said.

Mary Pols can be contacted at 791-6456 or at:

Twitter: MaryPols

Send questions/comments to the editors.

Comments are no longer available on this story