Adam Thurlow once ran the de-icing program at the Portland International Jetport. Winter day after winter day, as he watched the jetport’s trucks spray hundreds of thousands of gallons of de-icing fluid onto 737s, he was grateful that the spraying would keep the passengers inside safe.

But he also worried about where all that pinkish- orange fluid – the same stuff used in some kinds of antifreeze – was going after it mixed with snow and ice and entered the stormwater drainage system.

“You always had that in the back of your head,” Thurlow said, “Here we are with a fire hose, spraying the same material onto an airplane. It’s a crazy thought that we’re just letting that slip into our water and go out with the tide.”

Today, Thurlow is site operations manager for Inland Technologies, the company that created a recycling program at the jetport to recapture the superfluous fluid after it’s sprayed on planes and turn it back into de-icing fluid. It’s the first recycling program of its kind in the United States, and the Portland jetport recently became the first airport in the country to use 100 percent recycled de-icing fluid to de-ice aircraft. “Now we aren’t trucking fluid from 800 miles away to Portland,” said Paul Bradbury, Portland’s airport director.

Realizing the goal of using only recycled de-icing fluid has been a long time coming. In 2005-2008, when the jetport was planning and securing permits for its last major expansion, tests done by the Maine Department of Environmental Protection showed that propylene glycol, the active ingredient in de-icing fluid, was reaching the Fore River. The airport would have to address the issue.

“Propylene glycol in and of itself is nontoxic, but it has a high oxygen depletion factor when it breaks down in the environment,” Bradbury said. “So if you were to put a large amount into a smaller tributary, it would reduce the available oxygen and that would have a bad impact on fish and other biologicals in the stream.”

Portland typically must de-ice aircraft 80 to 90 days per year, depending on changing weather conditions.

Although de-icing hasn’t been a hot-button issue for environmental groups, Sally Stockwell, director of conservation for Maine Audubon, says many of the plants and animals living in a coastal estuary system depend upon clean water to be successful, so anything that helps keep the water oxygenated is a step in the right direction.

“Anytime we can recycle chemicals and keep them from getting into the ecosystem where they can have effects, it is a great thing, and I applaud the Portland airport for doing that,” she said.

Some airports, such as the Syracuse Hancock International Airport in New York, have constructed large nearby aeration ponds (similar to those used at water treatment plants) in order to add oxygen to the mix of stormwater and de-icing fluid. But that approach takes a lot of land, “and that’s something we don’t have,” Bradbury said.

So the jetport started building the infrastructure it would need for “passive collection” of de-icing fluid. That project was well underway when Inland Technologies was hired in 2010 to work with the jetport and Northeast Air, which runs de-icing operations at the jetport. Inland was selected for its experience recycling de-icing fluids made with ethylene glycol, the compound used at Canadian airports. Ethylene glycol is considered hazardous for human consumption in the United States, Thurlow said, but it is easier to recycle.

Here’s how passive collection works: Planes flying out of the Portland jetport go to a de-icing pad constructed with cut-and-grooved concrete so all of the de-icing fluid that runs off a plane flows into slot drains – long, narrow drains that are slotted like a grated drain – thus avoids the city’s storm drains. From there, the fluid drains into a half-million-gallon underground storage tank at adjacent Inland Technologies, where a recycling process separates the glycol from stormwater and distills it into a purer form that can be re-manufactured into de-icing fluid.

“When you look at it in a bottle at the end of our process, before you convert it back to de-icing fluid, it looks like a perfect vodka,” Bradbury said.

The jetport also does “active collection” of de-icing fluid using a “Glyvac,” a vacuum truck developed by Inland to suck up pools of spent fluid lying around on the tarmac just after it has dripped off a plane. (By comparison, Washington Dulles International Airport has 20 of the trucks.)

“If we can capture it as soon as possible with limited mixing, we have a higher percentage glycol, and then we save energy in terms of the process,” Bradbury said. “So we’ll run that vacuum truck to pick up very high concentrate right after a plane has de-iced. That keeps it from mixing with more snow and freezing rain and ice on its way to the trench drain.”

Nationally, all airports collect de-icing fluid in some way to comply with their stormwater discharge permits, according to Melinda Pagliarello, director of environmental affairs for Airports Council International in Washington, D.C.

“All airports either have a collection system or they’re working towards some kind of biological, on-site treatment,” she said.

Pagliarello’s organization has a water quality working group that is partnering with the airlines on a voluntary pollution reduction program.

“One thing operators have been working on is reducing the overall usage” of de-icing fluids, Pagliarello said. Lots of ordinary travelers have had the experience of watching their plane get de-iced, then get de-iced a second time because the first application has timed out. When determining when to de-ice, airport officials look at a set of tables that consider, among other things, weather conditions. The airline industry is trying to cut back on unnecessary de-icing.

“There’s a group that is installing at airports a collection system for snow and determining what kind of snow it is in real time so then they get better information on how long the de-icing is good for.”

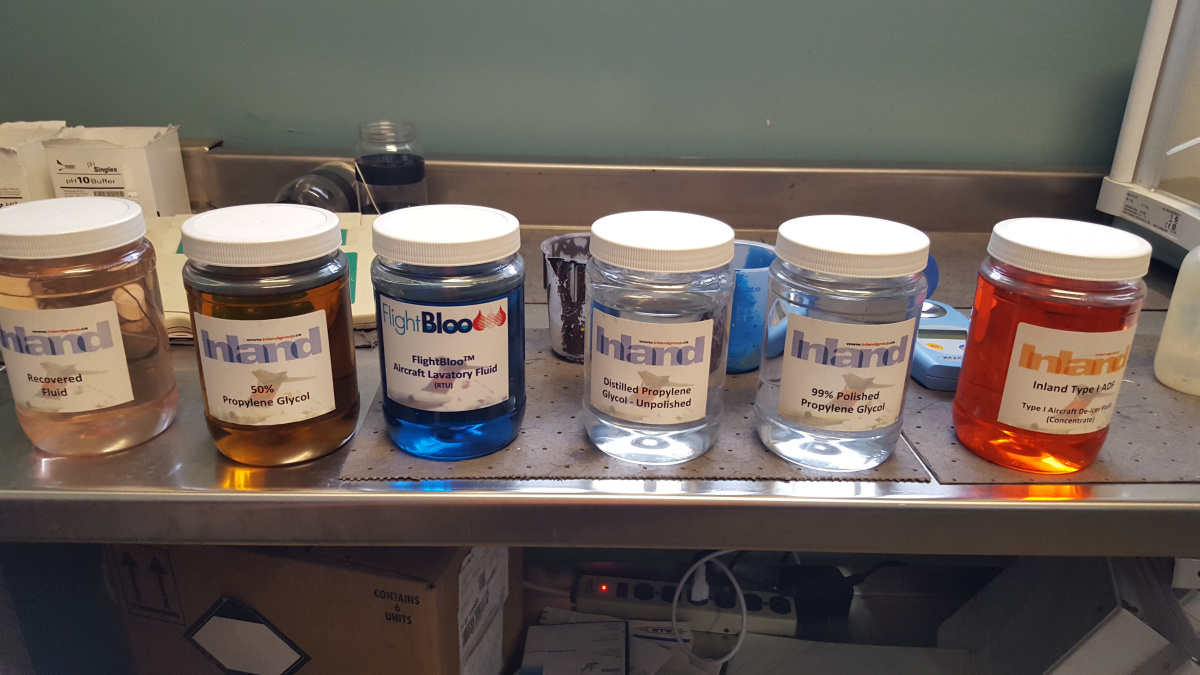

When Inland Technologies started recycling Portland’s de-icing fluid, it concentrated the used fluid to a 50-50 mixture of glycol and water and sold it to secondary industrial markets. Propylene glycol, according to Thurlow, is used in the manufacture of paints, in the offshore drilling industry, and in antifreeze for recreational vehicles. It can also be blended into aircraft lavatory fluid. It can’t, however, be turned back into de-icing fluid. The mixture must be distilled to 99 percent pure glycol for that to happen – and the Portland jetport is the only U.S. airport doing it. The 99 percent pure glycol is blended with a mixture of other ingredients, including dye and anti-corrosives, that turn it back into de-icing fluid.

Controlling the amount of de-icing fluid going into the environment can also have an economic impact. It takes about 150 gallons of de-icing fluid to treat a single 737, Bradbury said. Portland goes through about 100,000 gallons of the stuff annually – depending on the weather, of course – and while the price of de-icing fluid fluctuates, the national average is $6 a gallon. Spraying it out of a fire hose, Thurlow said, “it can really add up fast.”

“De-icing fluid is very expensive, so we’re at a disadvantage to some of the southern airports,” Thurlow said. “Now when you add an environmental collection program, you’re adding to that cost.”

So, about a year after Inland started the Portland recycling program, the company and jetport officials began looking for ways to lower the overall operating costs of the program.

They started by accepting used de-icing fluid from other airports that Inland works with. Some of them do partial recycling, concentrating the fluid up to the 50 percent glycol level, and some just collect the raw stormwater that contains the fluid. Fluid is regularly shipped to Portland for recycling from airports such as Dulles International Airport, Reagan National Airport and Andrews Air Force Base, all in Washington, D.C.; from Bradley International Airport in Connecticut; from Newark Liberty International Airport in New Jersey; and from LaGuardia Airport in New York City.

A year after Portland started accepting spent de-icing fluid from other airports, it also started taking in glycol from other industries, Thurlow said, “so we took ourselves out of the airport world and opened ourselves up to anybody who needed our services.”

Their clients include some local businesses, such as Shipyard Brewing Co., which uses glycol in its cooling tanks, and Unum, which uses it in its heating, ventilation and air conditioning system.

Today the jetport recycles an average of one million gallons of de-icing fluid each year, Thurlow estimates. Half of it is Portland’s own fluid, the other half from elsewhere. Bradbury hopes that eventually the cost of de-icing a plane in Portland will be less than at any other airport in the United States. “We aren’t there yet,” he said, “but we’re getting closer.”

Thurlow and Bradbury say they expect to see other airports follow Portland’s lead. This type of recycling is “a very, very new industry,” Thurlow said.

“I believe you’ll see a lot of areas follow suit,” he said. “We’re definitely creating a new concept here.”

Comments are no longer available on this story